-

Over 90 Years

industry expertise

-

Largest

facility & product range

-

Leaders

in the technology market

-

UK Based

service department

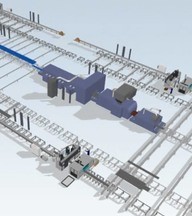

Automated Steel Processing and Factory Automation

Automated steel processing and factory automation enables fabricators and steel service centres to optimise material handling and processing efficiency within their plants.Using smart decision-making and control technology, multiple processes can be automated and operated simultaneously to maximise system efficiency within the smallest possible factory footprint.

Over the years we have witnessed that many fabricators & steel stockholders have grown their facilities and corresponding material handling system to give them the type of equipment & handling options that it’s believed would increase productivity. Our Intelligent steel processing blows away the old myths that you need expansive equipment with numerous material handling system and numerous handling options to achieve a leg up on their competition.

Intelligent steel processing starts by enabling a fabricator or service center to simulate a job or production sequences in conjunction with his erection needs to optimise the fabrication process. Once the optimum sequence is determined, the material can be loaded and then scanned onto the material handling system to start the process. The Win-Handling software then optimises the handling steps, process selection and completes the fabrication operation in the most efficient manner and without the requirement for the programmer/operator to directly drive the programming and system operation.

As material is run through the system, the routing and corresponding CNC programs for the different operations of shot blasting, sawing, drilling, thermal cutting and layout occurs automatically and without an operator's decision making or direct involvement in the manual operation of the CNC equipment.

All of the material handling functions occur in “mask time” as their operation is also not controlled by a team of operators who determine what throughput your system will generate. All functions, including the material handling operations, transpire simultaneous with the CNC systems so the process is running at its maximum efficiency. The elimination of the decision making operation and its timing through 'Intelligent Fabrication' makes sure that maximum system efficiency is always achieved in the smallest possible footprint.